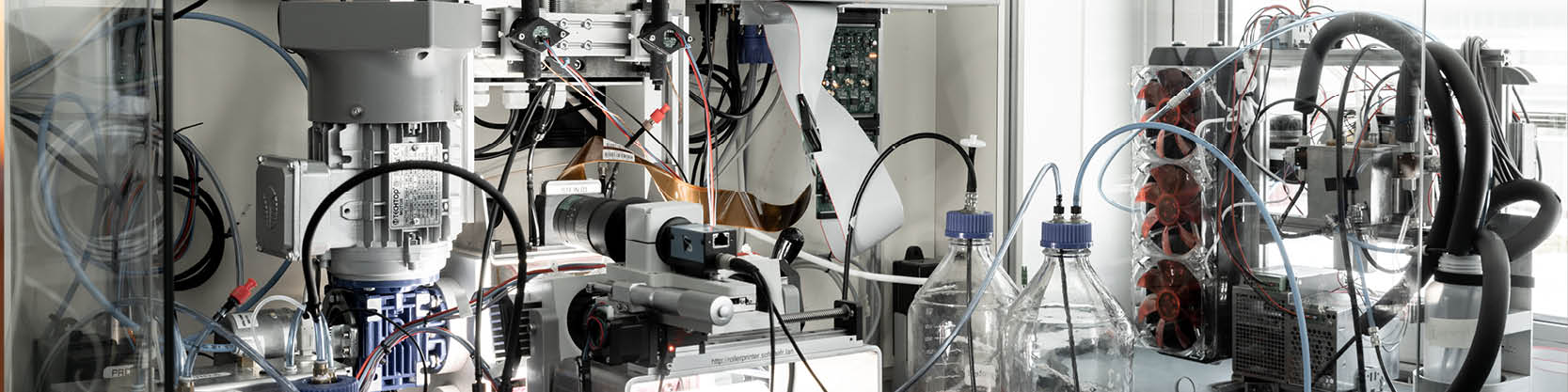

When today’s inkjet technologies are not enough to fulfil the requirements of a given process, iPrint will make the impossible possible through innovative technology developments. We are currently working on the development of new technologies in the following domains:

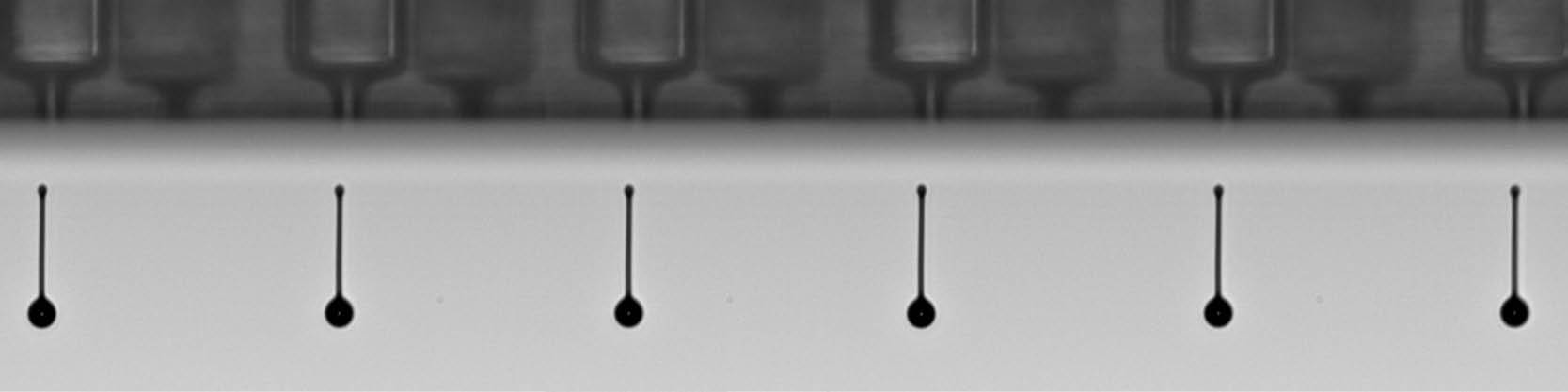

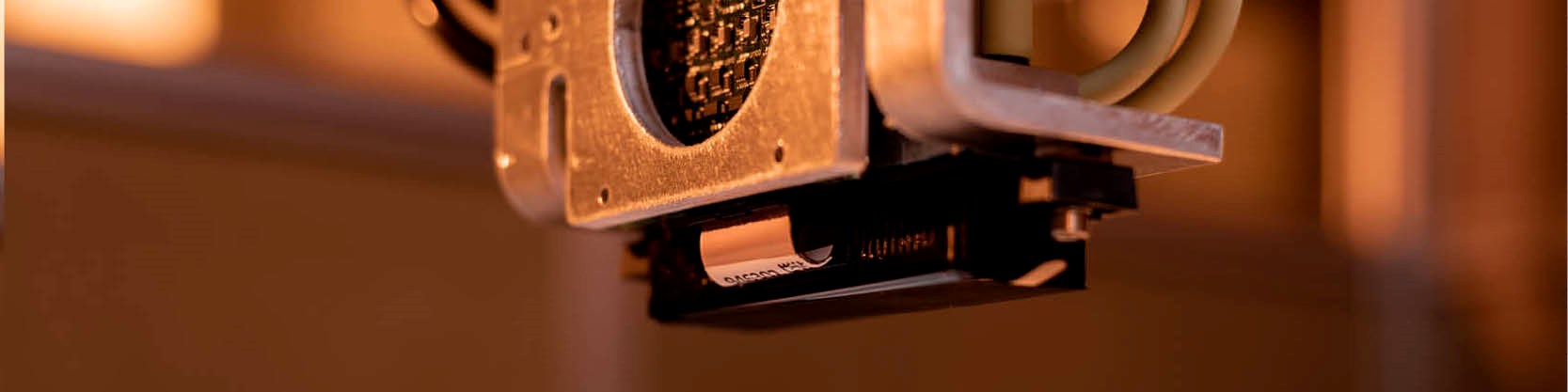

For the inkjet of the future, iPrint is researching and developing several core technologies that will expand the capabilities of inkjet printheads and add new features.

Inkjet is now being used for printing on 3D objects as well as on 2D, and iPrint is researching and developing the required technology to meet these new challenges in "direct-to-shape" printing.

Having mastered the handling of various ink types, iPrint is doing R&D on the technologies needed for the ultimate ink supply system.

iPrint is researching and developing basic plasma treatment as an on-demand technology for surface modification, just as inkjet is an on-demand technology for printing.

By combining the most suitable technologies and materials, iPrint is developing and optimizing inkjet-based digital printing processes in a variety of domains. These can be grouped into:

With the aim of improving product performances, developing new products and reducing environmental footprints, iPrint is working on the development and application of new graphical inks for the packaging, automotive, toy, watchmaking, building materials and graphical industries.

From printing living tissues for regenerative medicine, to biosensors and bioresorbable stents, iPrint develops a variety of digital printing processes for the biomedical and pharmaceutical industries.

Inkjet printing and other digital printing technologies have been employed to fabricate new or personalized edible products.

Several analog printing processes like screen printing have been digitalized at iPrint thanks to inkjet technology, enabling the fabricattion of sensors, multi-functional structures, energy storage devices, coils, etc. Printing and post-treating different materials as conductive, dielectric as piezo-resistive to form multilayers is a technical specialization at iPrint that is enabling the manufacturing of new smart devices in the medical, aerospace, IoT, automotive, and sports industries.

By combining inkjet printing with other digital techniques such as direct-ink-writing, material extrusion, FDM, pick-and-place, etc. iPrint has succeeded in developing hybrid processes with multi-materials and in overcoming the limitations of individual processes to develop new products. iPrint has also successfully developedvarious binder jetting (BJT) and solvent-on-granule jetting (SG-3DP) processes.

By continuing to browse this site, you agree to the use of cookies to improve your user experience and to provide website statistics.