Project

Inkjet-printed Multifunctional Thin-ply Composite Structures

PROJECT SUMMARY

| Funding type | HES-SO |

|---|---|

| Duration | 2019 - 2021 |

| Research area | Advanced Manufacturing |

This project is part of the EcoSwissMade HES-SO Research program funded in 2019 between Comatec of HEIG-VD and the iRINT Institute of HEIA-FR.

The main objective of the project is to develop and evaluate digital additive manufacturing solutions as well as testing, design and analysis methodologies, to allow multifunctional integration of electronic, communication, power distribution and diagnostics in high-performance composite structures. While these technologies are widely used for signal and power transmission paths, embedding them into a principal structure implies a large compromise on the topological and geometrical aspects of the structure as well as its strength capabilities.

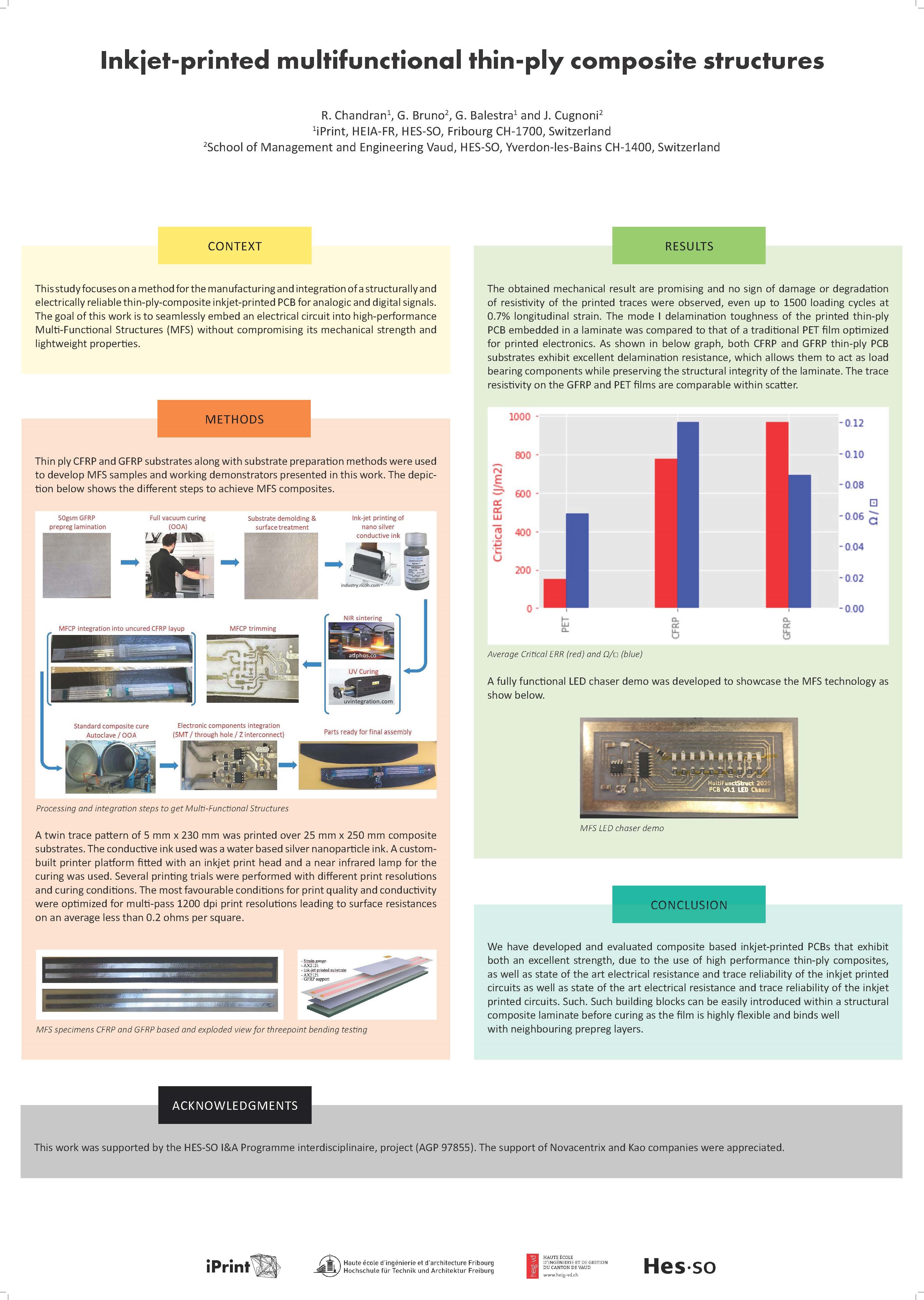

This study focuses on a method for the manufacturing and integration of a structurally and electrically reliable thin-ply-composite inkjet-printed PCB for analogic and digital signals. The goal of this work is to seamlessly embed an electrical circuit into a high-performance composite structure without compromising its mechanical strength and lightweight properties.

Two types of substrates were used to develop a reliable and efficient inkjet printing and surface preparation method on thin-ply composites. Silver nanoparticle ink was deposited by inkjet printing and sintered on these substrates either by using a near-infrared lamp or chemically to create conductive traces either in the form of parallel twin traces to assess the electro-mechanical properties of the sample or in the form of a PCB. The digital manufacturing of the latter was completed by an extrusion method to deposit conductive epoxy dots on which the different components of the PCB were deposited by a pick-and-place technique.

The samples exhibit both excellent strengths, due to the use of high-performance thin-ply composites, as well as state-of-the-art electrical resistance and trace reliability of the inkjet printed circuits. Such a building block can be easily introduced within a structural CFRP laminate before curing as the film is highly flexible and binds well with neighbouring prepreg layers.

This multifunctional composite manufacturing technology has excellent potential thanks to the weight gain and therefore energy savings (aeronautics, space, transport), but also in terms of increased value-added by part (product with high added value and automation) and as a basis for the integration of the Internet of Things (monitoring, quality, feedback).

Partner - HEIG-VD Institut COMATEC

By continuing to browse this site, you agree to the use of cookies to improve your user experience and to provide website statistics.